What is the 360° Diagnostic?

It’s a support program that enables Walloon companies to highlight opportunities for improving their logistics processes. Thanks to a methodical approach based on a detailed questionnaire followed by an in-depth analysis in the field, this tool offers a complete vision of your supply chain.

The expert carries out the diagnosis on operational processes, and then examines their strategic coherence as well as their financial impacts. The purpose of this diagnosis is to draw up an inventory at a specific moment in the organisation, and provide an overview while identifying points for improvement.

After an inventory of logistics issues, the expert proposes ideas for solutions or, alternatively, redirects the company to other professionals to go further in implementing solutions, or even to benefit from an in-depth audit on a particular element.

Advantages

Concrete 3-day program

Expert in field analysis

Concrete and fast actions

Professional networking

The 360° Diagnostic concerns any Walloon company that generates transport and logistics operations.

The benefits?This tailor-made program will enable you to identify areas for optimization, increase your competitiveness and strengthen your company’s overall performance.

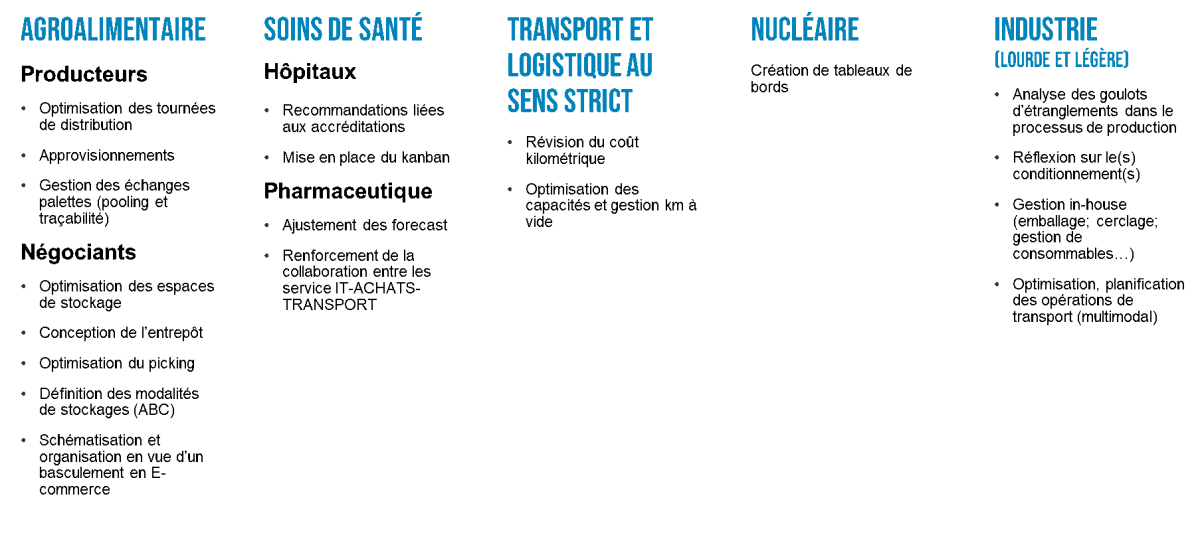

The case studies:

The 360° Supply chain Diagnostic is carried out in 5 phases spread over a total of 3 days:

- Screening – This first stage provides a synthetic description of the logistics and supply chain situation. It is carried out by the company, using an existing form, and prepares the way for the next stage.

- Diagnosis – The actual diagnosis is carried out, on site, with the person(s) designated by the company. The expert asks questions and encodes the results in the corresponding diagnostic tool. This expert also provides any clarifications and examples required, and can go into greater depth on any elements of the diagnosis that seem to have most room for improvement.

- Diagnostic analysis and report – On the basis of the information collected during the diagnosis, the expert analyses the results obtained through the diagnostic tool, expresses the level of supply chain maturity obtained, and highlights avenues and elements for improvement. In the diagnostic report, the expert highlights the points that need to be unblocked in order to reach the next level of maturity. Through findings and recommendations, the expert shares advice and comments to address the blocking points that when resolved will enable us to gain in supply chain maturity.

- Restitution review – If requested.

- Diagnostic follow-up, within 6 to 18 months

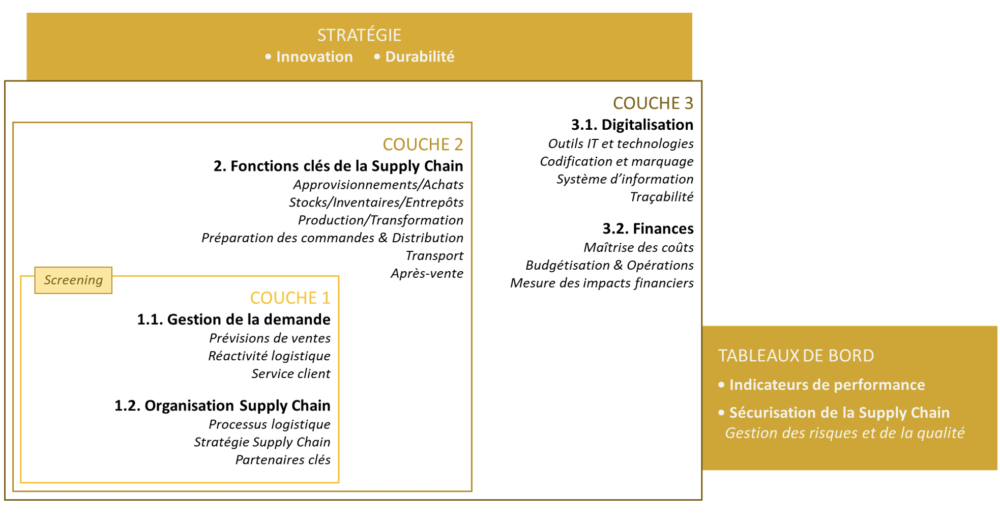

The analysis carried out by the lead diagnosis expert follows a architecture in 3 layers, completed by global pillars. In all, the diagnosis is made up of 13 analysis modules. Some are not covered if not relevant to the company:

| 1. Demand management

2. Supply chain organisation 3. Procurement/Purchasing 4. Inventories/Inventories/Warehouses 5. Production/Processing 6. Order picking/distribution |

7. After-sales

8. Digitalisation 9. Finance 10. Performance indicators 11. Securing the supply chain 12. Strategy |

The results obtained through this analysis are based on a Supply Chain maturity benchmark, which is used as follows by Logistics in Wallonia:

| Basic | The Basic Supply Chain. This level of Supply Chain maturity corresponds to the lowest level of this benchmark. The company is unable to meet demand and satisfy its customers (e.g. stock-outs, late deliveries, raw material shortages, etc.) |

| Fragmented | The fragmented Supply Chain. Logistics and the Supply Chain are approached as a series of functions treated individually without forming a whole, an overall process. It operates in reaction to actual demand, but does not anticipate its activities. |

| Excellence | Internal excellence. The company demonstrates real mastery of its activities by planning and anticipating their development. It also works to optimise these activities. |

| Integration | Integration of partners. The company extends its versatility and range to its key partners because it understands the role that they play in the overall performance of its Supply Chain: it applies to the extended enterprise concept. Thanks to this, it has excellent visibility over the entire chain, and controls its flows in real time. |

| Collaborative | The Supply Chain collaboration. The company collaborates in real time with its partners around common objectives, supported by monitoring of key indicators and periodic steering committees. It is through collaborative processes that flows are tracked, controlled and optimised from one end of the chain to the other, thus optimising efficiency, reliability and performance of the Supply Chain as a whole. |

- Cluster members: FREE

- Non-members: €4500

- Walloon industrial SMEs: FREE with the support of the digital innovation hub WalHub (until 31/10/25)